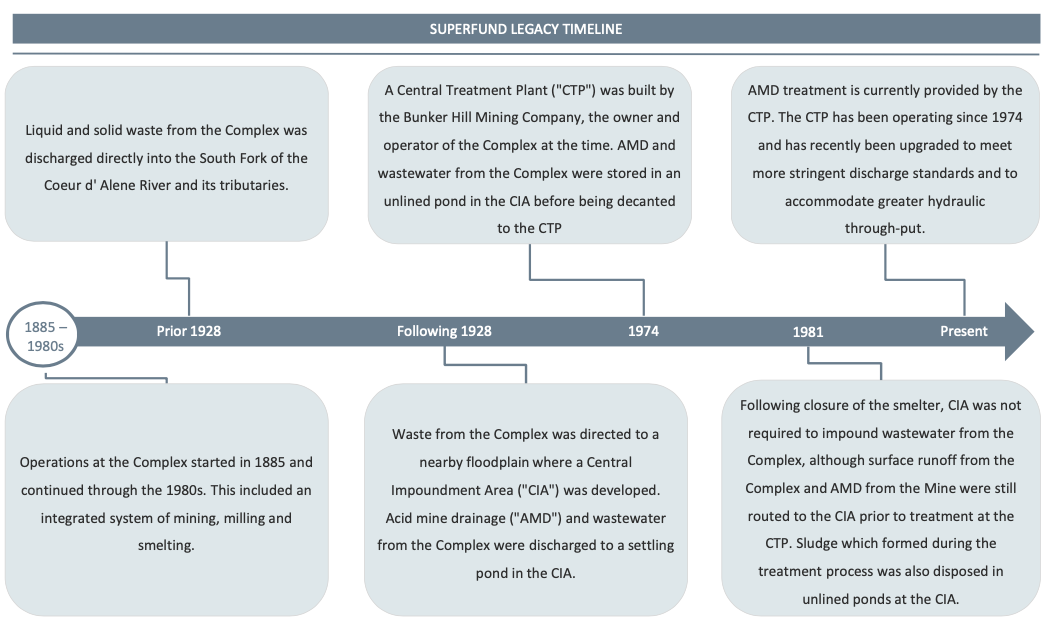

Where we started

When Bunker Hill started exploration in March of 2020, there had been very little rehabilitation and maintenance work performed in Bunker Hill Mine since 1991. However, Bunker Hill has taken action to change this for the better.

BEFORE March 2020: Ground Water Improvements

AFTER March 2020: Ground Water Improvement

Activities in motion

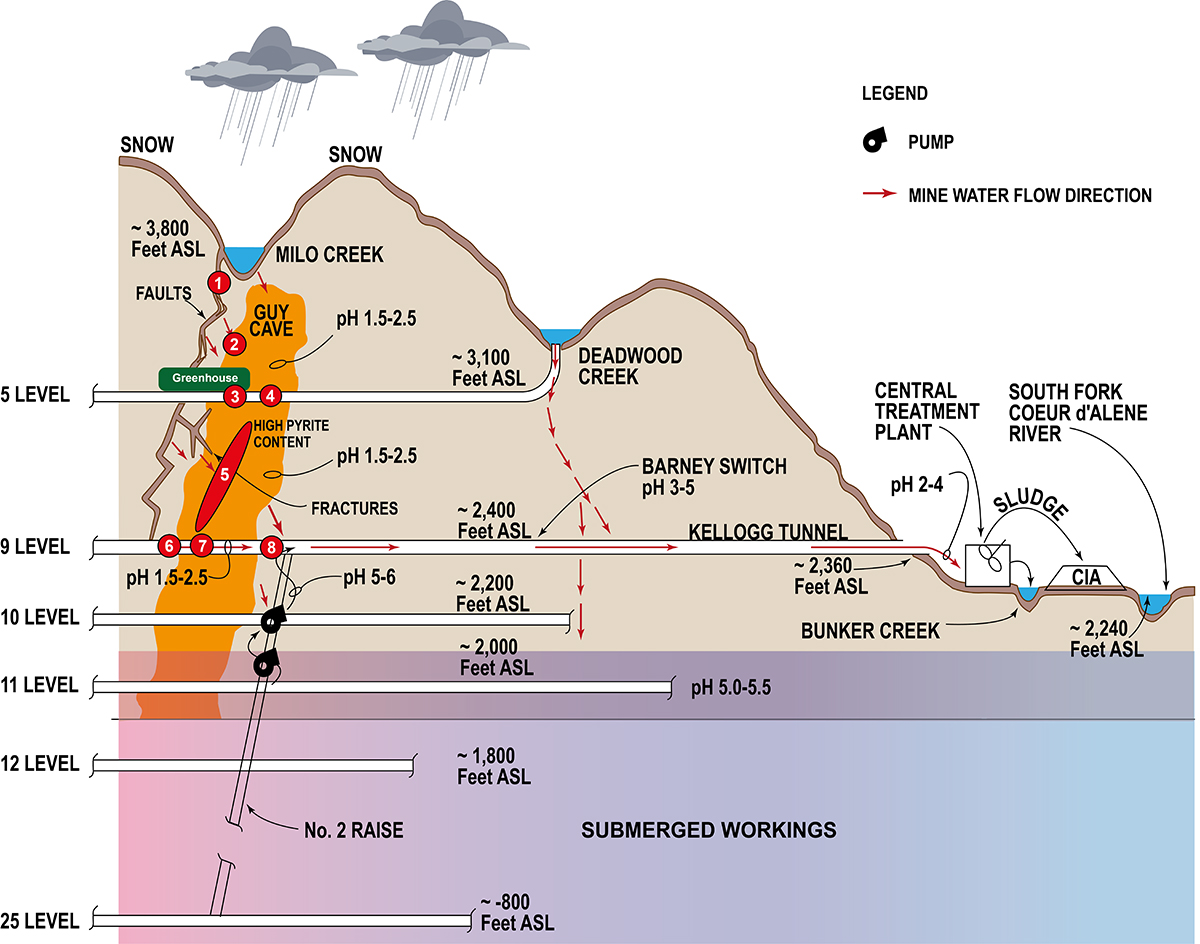

In September 2020, Bunker Hill initiated a water management program that focuses on three main activities:

- Facilitating water flow through the mine’s system;

- Collecting and controlling the worst water in the mine and

- Treating the worst water flows so that mine effluent quality is improved significantly before it leaves the mine.

Pool prevention / Reduce in-mine water retention time

- Greenhouse removal

- Removal of crossbeams

- Clearing cave-ins

- Removing dams

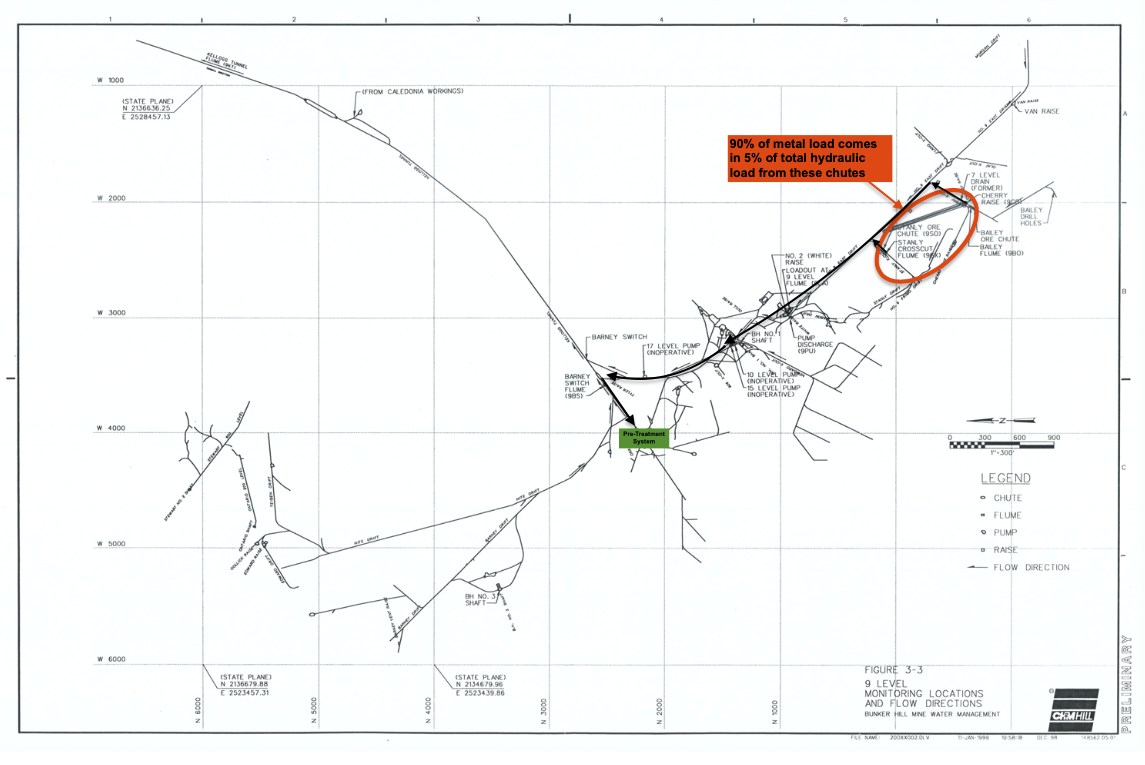

Collect and control water streams

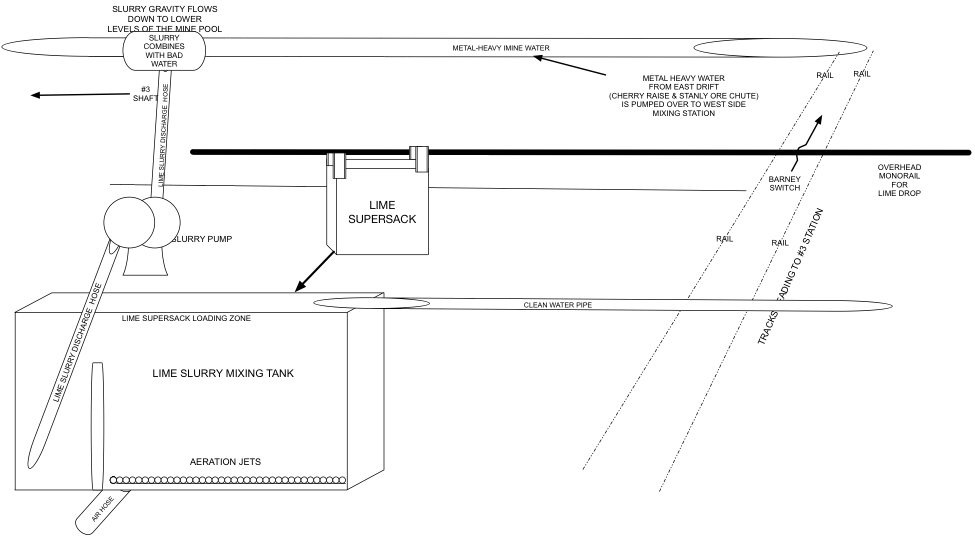

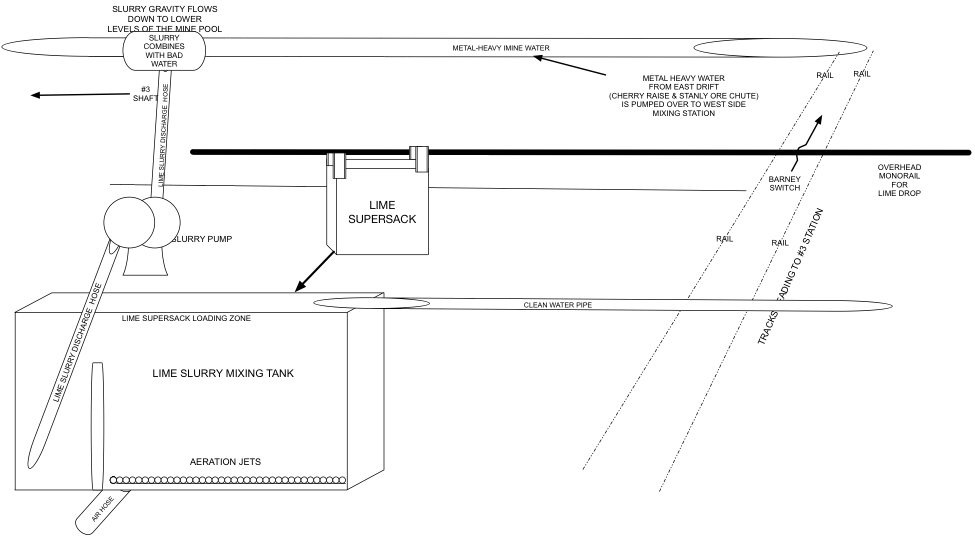

Pre-Treatment System:

- Bad water flows in the East Drift pipe to a lime treatment system

- The system elevates pH and precipitates metals in a sludge

- Sludge is piped as a slurry to a sealed area of the mine, where it remains alkaline

- This system results in a 70% reduction in the metals that leave the mine

- Performance testing results for the system will be available online starting in March 2021

Impact monitoring

We believe that providing access to information is essential for stakeholders and the general public to develop an adequate understanding of our environmental management program. Sharing a common understanding with our stakeholders is essential to meaningful and productive dialogue that leads to positive outcomes for the whole community.

Bunker Hill monitors 29 locations in and around Bunker Hill Mine on a continuous basis. This includes 10 surface locations and 19 locations inside the mine. Monthly samples are submitted to nearby a laboratory, Silver Valley Analytical (SVL). We collect additional information every two weeks. Water samples are collected in accordance with strict QA/QC protocols to ensure data integrity – our Quality Assurance Project Plan (QAPP).

- Monthly lab testing

- Time series for key locations (Sept – Dec 2020 so far)

- Kellogg Tunnel (9 Level)

- Greenhouse (5 Level)

- Crusher Station (6 Level)

- Flood Drifts (7 Level)

- Cherry Drifts (7 Level)

- Cherry Drifts (8 Level)

- Cherry Raise (9 Level)

- Stanly Ore Chute (9 Level)

- Mass balance sheets

- Monthly 2020 Sept – Dec (these need to be created)

- Bi-weekly field parameter time series (Sept – Dec 2020 so far)

- Kellogg Tunnel (9 Level)

- Greenhouse (5 Level)

- Crusher Station (6 Level)

- Flood Drifts (7 Level)

- Cherry Drifts (7 Level)

- Cherry Drifts (8 Level)

- Cherry Raise (9 Level)

- Stanly Ore Chute (9 Level)

Future activities

Bunker Hill is committed to designing a project that will leave the environment in a better condition than when we found it. We continue to develop future initiatives that will further improve the water quality of our community.

Clean water capture/control system

Preventing good water from mixing with bad water in the mine, has three main benefits:

- It allows for a smaller, more effective water treatment solution

- It allows the water to be used productively inside the mine and

- It allows for the possibility of productive use on the surface at the point of discharge.

We will develop a pipe system that captures and control good quality water in the mine in Phase 2 (started in August 2020).

Long-Term Water Treatment

We are working with environmental engineering firms and water treatment experts to determine the optimal long-term water treatment solution for Bunker Hill Mine. Active engagements involve:

- Stantec

- MineWater

- Klepfer Mining Services

Source Control Research

Surface water above Bunker Hill Mine is very good quality water. It degrades quickly after entering the mine through thousands of fissures and fractures in near-surface rock. This is where we believe the best long-term water management system is source control. It is the process of preventing water from entering the mine in the first place.

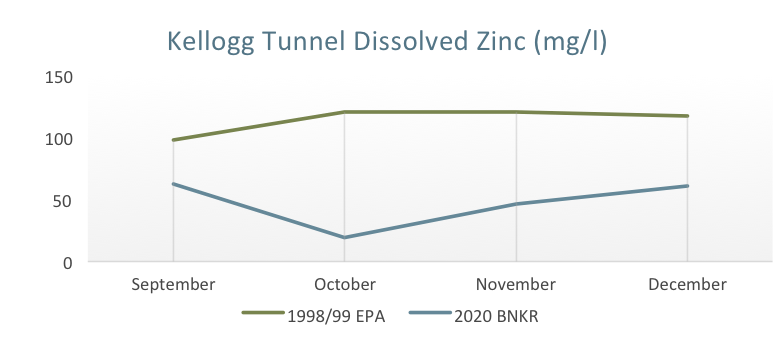

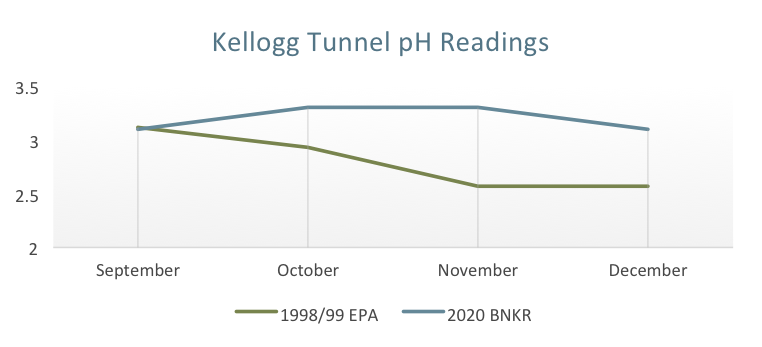

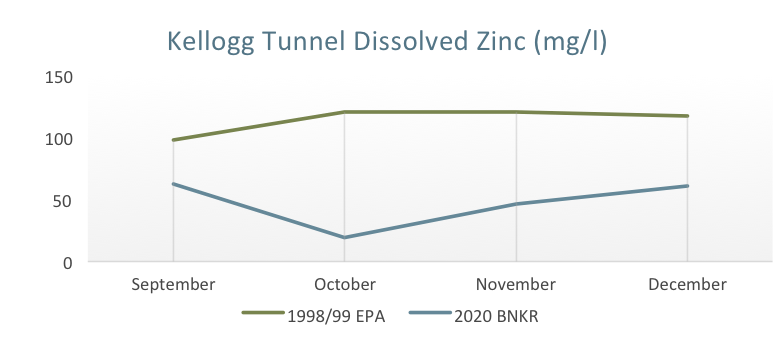

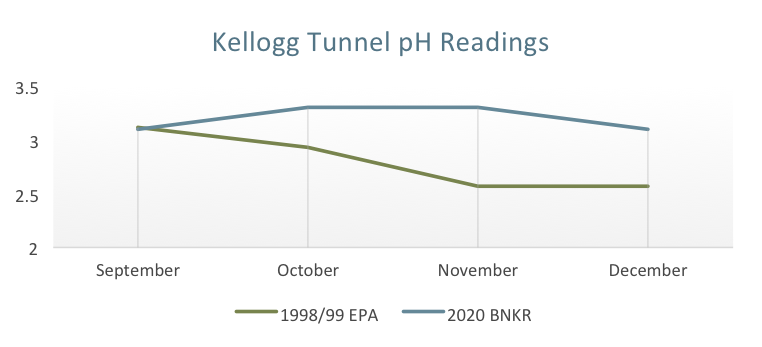

Water quality has improved since the Phase 1 water management program began. The graphs below compare the water quality when in-mine research was last conducted by the EPA in 1998/9 versus when Bunker Hill initiated the water management program in Sept 2020.

Kellogg Tunnel Dissolved Zinc

Kellogg Tunnel pH Readings

While it isn’t feasible to seal all entry points, Bunker Hill will use studies conducted by the EPA as a starting point for water system modeling. We will also invest in additional studies to improve upon this understanding and engineer solutions that will reduce the volume of water entering the mine going forward. These studies will begin in August 2021:

Beneficial Uses of Water

Once clean water in the mine is isolated and controlled, it may be of suitable quality for use in a range of activities that will be beneficial to the local economy.

- Snowmaking

- Agriculture

- Municipal uses

Lake Coeur d’Alene

Bunker Hill will look for ways to improve fish habitat and water quality in Lake Coeur D’Alene in partnership with local stakeholders